ARMS Solution - Efficient and Simple

Challenges- Link between equipment conditions and business efficiency. Bad conditions and missed maintenance lead to low efficiency.

- Link between equipment conditions and business risks. Bad conditions and incorrect maintenance lead to high risks.

- To determine budget size,limits and constraints we need well-informed arguments.

- Budget allocation is especially important when constraints are tight.

- After the budget is allocated -control of actual expenses is important for next cycle.

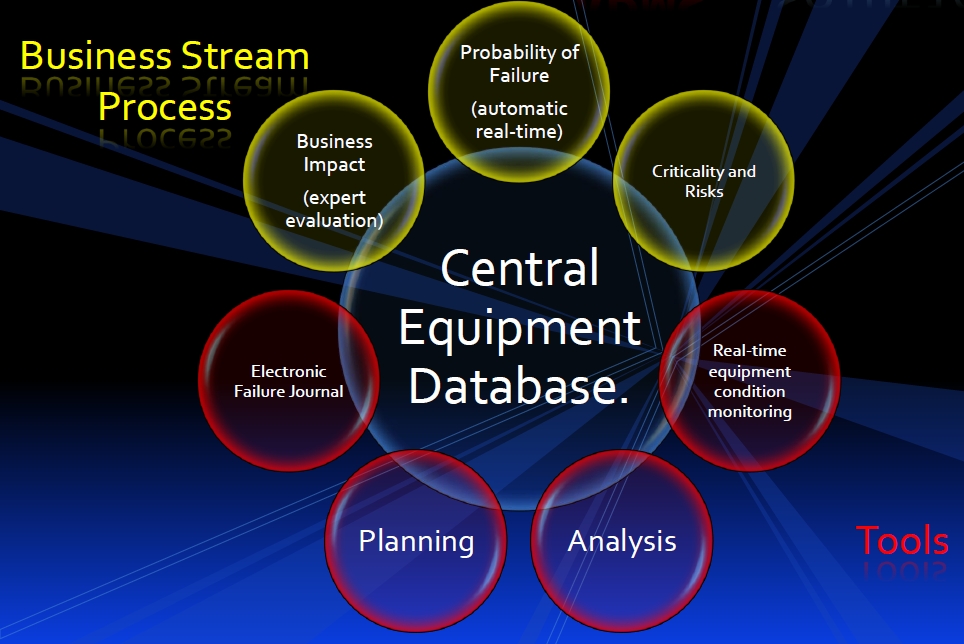

Tasks

- Collect information about equipment conditions and repairs.

- Evaluate and record operational conditions, probability of failure,business impact and required maintenance and repair for every equipment.

- Automatically recommend preventive maintenance and repair tasks based on analysis of equipment conditions and failures.

- Determine budget allocation in real-time to minimize outages and maximize profits.

- Analyze efficiency of expanses and performed repairs.

ARMS Solution - software and processes

Result: Optimize your business - Control and analyze multiple plants and units.

- Optimize preventive maintenance and repair activities while maintaining maximum profits by minimizing risks for critical equipment.

- Evaluate every expense and operational task using real-time, objective and proven criteria based on business risks.

- Cost of ownership analysis based on actual and planned expenses,business impact and probability of failure using scenarios to determine the need to replace equipment for multiple goals.

- Lowering expenses for non-critical equipment allows minimizing budget and reallocating money to maximize profits.

Result: Real-time management

- Real-time control of equipment conditions, probability of failure, repairs, preventive maintenance procedures, expenses planned and actual.

- Focus technical activities on preventive maintenance to minimize failures and maximize profits.

- Determining non-critical equipment allows run-to-fail operation mode without risks to business.

- Automatically generate efficient and optimal preventive maintenance tasks for critical equipment.

- Correctly prioritize budget, resources and maintenance tasks based on criticality analysis and actual probability of failure for every equipment.

- Clear reports and task lists available real-time to every person.

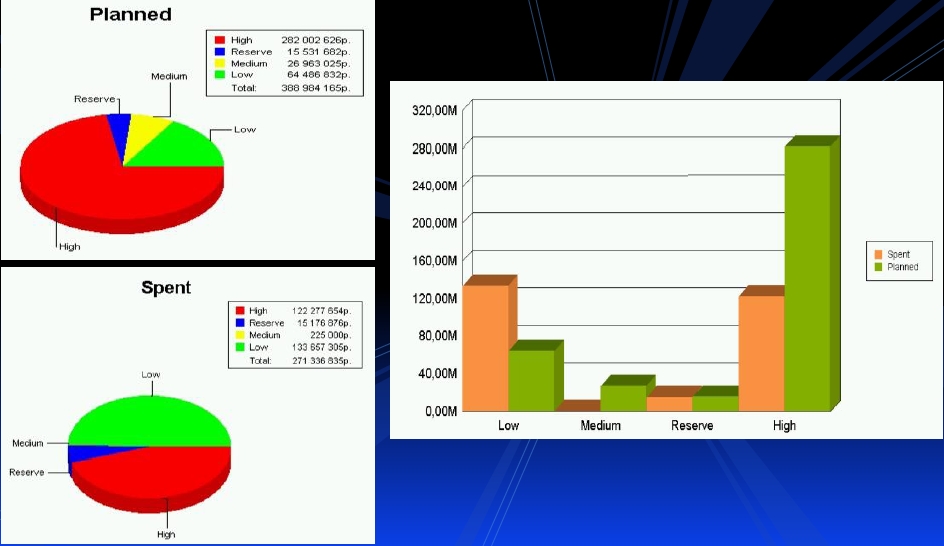

Result: Budget Analysis

Save at least 10% of your budget by correctly prioritizing required tasks and reducing expenses for non-critical for business equipment.

Result: Reduce Failures and Maximize ProfitsMaximize profits by focusing maintenance and resources on critical for business equipment.

Minimize critical equipment failures by optimizing preventive maintenance and correctly prioritizing budget and resources.  All images are actual results generated using our ARMS Solution. Contact us for more information and to schedule demonstration!

|